Have any questions?

+44 1234 567 890

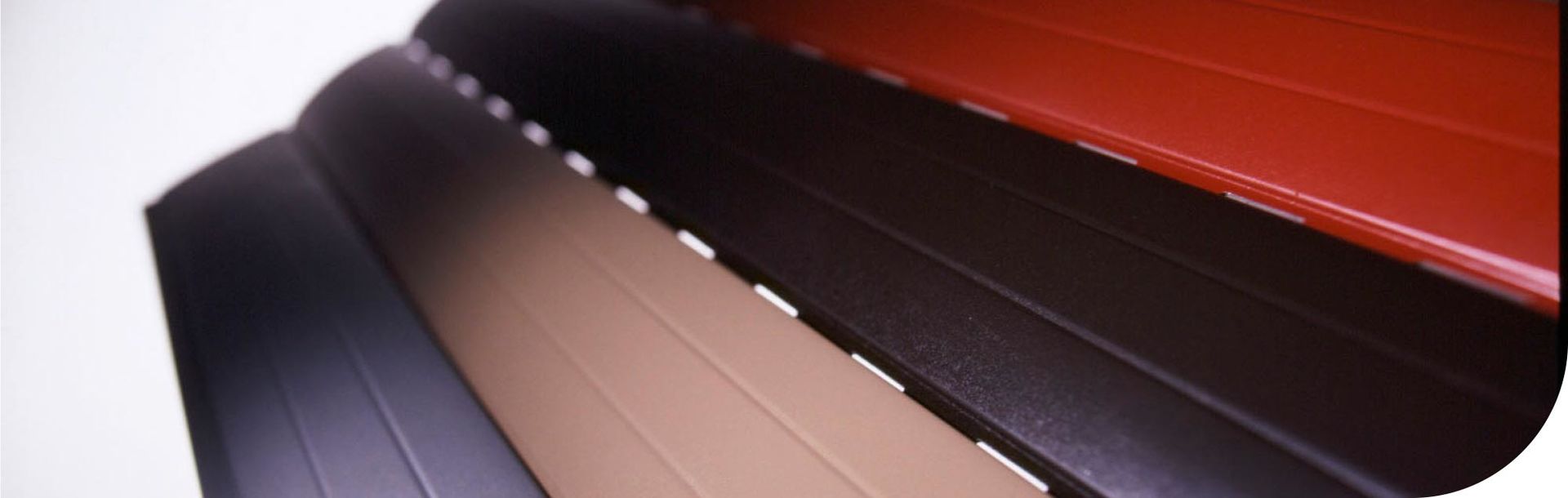

LUXECOAT LIQUID

Quality Custom Designed Solutions

LuxeCoat Liquid comprises the entire range of potential wet paint coatings in the coil coating process. Depending on the customer’s specifications, the paint systems and aluminum alloy can be randomly combined.

At the otefal coating GmbH, the customer’s satisfaction is priority one. Consequently, we offer optimum services prior and post purchase, first class technical customer service support and the time-tested capability to promptly implement market demands. The focus is always on flexibility.

Tradition is a commitment: LuxeCoat S.r.L. / Otefal S.p.A. boast 30 years of manufacturing experience, which is paired with many years of sales expertise of the newly established otefal coating GmbH team. These merits make us the ideal partner for demanding and successful customers.

We offer optimum solutions for the problems and requirements of our clientele.

A VERSATILE PRODUCT FOR MANY APPLICATIONS

TECHNICAL DATA

Product description

Wet paint coil coating produces infinitely coated semi-finished aluminum products. The process applies a polyester, PU/PA or PVdF paint coat to the product.

Applications

Façade siding for new and existing buildings in custom and industrial construction, advertising signage, encasings for brown and white goods (appliances) and a wide arrange of industrial applications.

Fire prevention

Class A2, non-combustible

Processing

Depending on the painting system utilized and the condition of the base medium, wet paint can be bent without cracking up to 180 degrees based on an interior bending radius of min. T1.

Alloying

Standard Series 3 alloying, all other alloys available based on customer specifications

Dimensions

0.30 – 3.00 mm, widths of up to 1,500 mm, lengths of up to 6,000 mm, extended lengths and split strips from 10 mm band with upon request

Strength/resilience

H42 / H44 / H111 in accordance with EN Standard 1396

Coating

Polyester, PU/PA or PVDF, depending on the application, one-sided or double-sided decorations

Visual end

2-layer construction, 5-7 µ primer and 15-17 µ cover paint

Rear

About 3 µ protective paint or primer, suitable for glue adhesion or foaming. Double-sided paint decorated like the visual end.

Paint layer thickness

Decorative approx. 22 mµ, protective paint approx. 3 mµ

Gloss

Standard about 35 units, special gloss levels 20 – 100 units and surface structures in compliance with customer specifications upon request

Color palette

All-encompassing assortment in single colors, metallic, structured paint

Protective film

Transparent or white

Quality

In compliance with all European Standards, ECCA, EN 1396

Sewage Legislation

No special precautions necessary pursuant to ATV-DVWK-M 153, since no damaging heavy metal contaminants are present.

Recycling

Wet painted aluminum can be readily returned for recycling

A VERSATILE PRODUCT FOR MANY APPLICATIONS

Easy to process, easy to install, esthetically sophisticated. Wet painting processed aluminum is the ideal and cost effective solution for use in the manufacturing of industrial products in all types of applications.

State-of-the-art production processes deployed in coil coating applications of aluminum rolled products establish LuxeCoat liquid as an indispensable solution for a vast range of applications. Moreover, the utilized two-layer process painting systems (primer + cover paint) boast excellent, long lifecycles. The colors and sheen survive the test of time and the specific coating processes make the materials resistant to contaminants and environmental effects.

otefal coating GmbH

Seestraße 1

74232 Abstatt

Germany

+49 (0) 7062 6677 07-0

info@otefal-coating.de